Contract RTD, Blending and Co-Packing

An important part of our business mix for many years has been the incorporation of blending tanks into our Packaging cellar which are utilised for blending, chilling and carbonating many kinds of beverages.

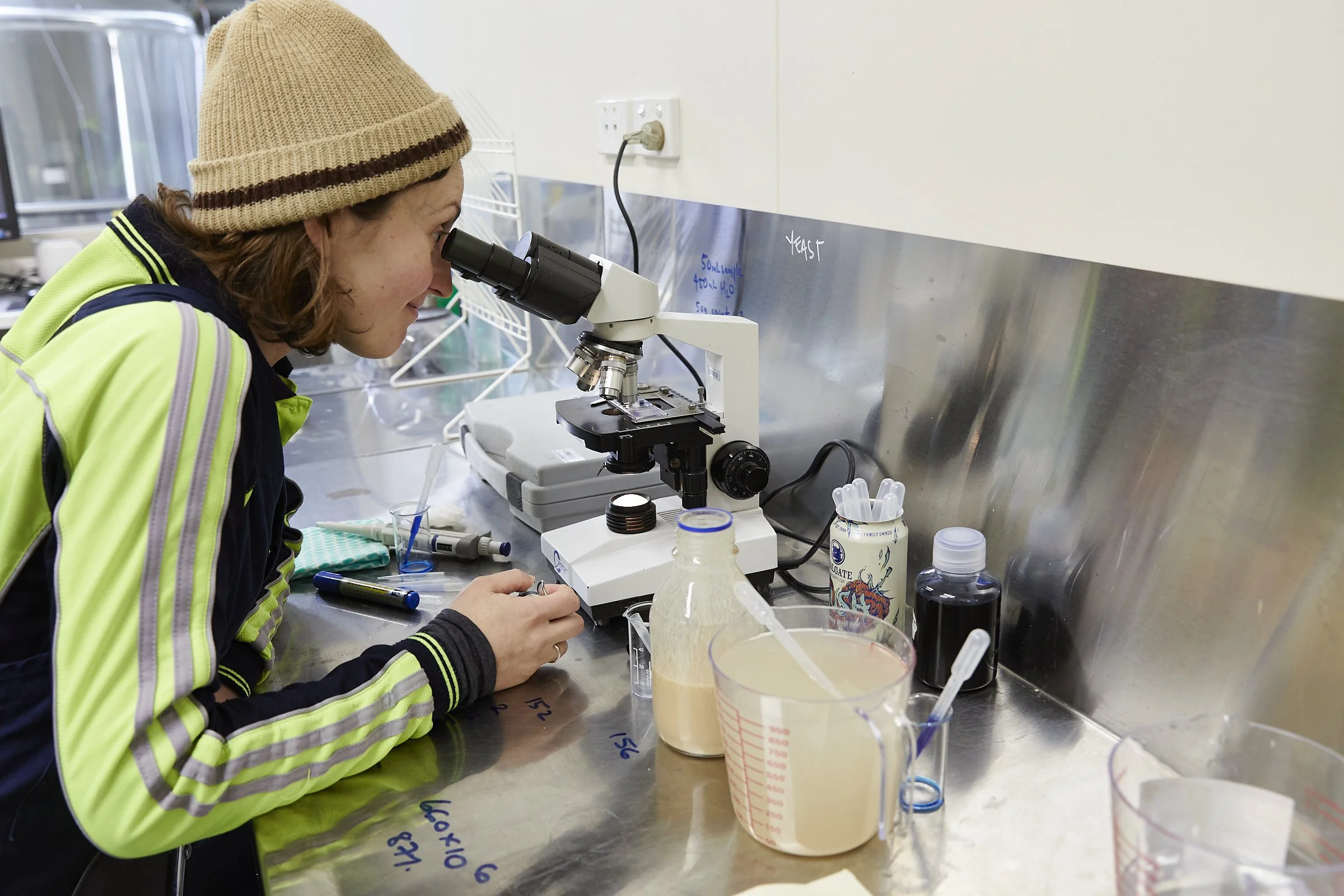

On-site Blending and Testing

Options are fully blended on site, or brought in finished product in tankers or IBC for packaging only e.g. cider, waters, wine

RTDs - All kinds of ethanol and spirits-based RTDs

Wine-based blends

100% wine for still or sparkling, canning and bottling

Ciders

Sparkling and mineral waters

Pickle Juice

Isotonic and other Sports drinks

Fruit juices

Why Choose Us?

Flexibility – we can split a single batch into Can and kegs or bottles and kegs

Recipe Development – matching an existing product of yours, or competitor example, with laboratory trials and small 1 litre blends. We have a formulation expert on our team and many years of experience in creating a mixture of flavours, balancing sweetness, acidity, mouthfeel and creating high drinkability products

On-site approval of first batch prior to going into packaging is available

Pilot batches – we can provide down to 1,000 litre first time batch of your product for market intro.

Fast Turn-Around – NPD release taking only 6 weeks from approval of art-work, and typical turn-around from Order to fulfilment on existing products is 14-20 days.

Pasteurising – while there is no post-pack pasteurising, we can bulk pasteurise and flash-chill your beverages prior to packaging

Preservatives – for additional insurance on shelf life stability we alternatively or additionally use natural plant based preservatives that are proven to inhibit any micro growth, backed by multinational technical support, and have non-sensitive labelling requirements.

Please ask for more information.

Learn More:

Recipe & Product Development ~ Beer Brewing ~ Seltzer Brewing